Clean Room Units, Inc. manufactures a line of excellent clean room gear designed to chop clinical tubing, expand tubing and insert barbed fittings into most forms of flexible tubing. We also manufacture guide and automated go through windows designed for clean rooms.

High volume cutting on the tabletop. Our good quality clean room offer shop has medical tubing cutters that span all industries and nearly all tube dimensions and will allow rapid, correct cuts wherever precision is paramount.

Whilst retaining correct particle counts is very important in design and operation, a protocol designed to recognize practical particles ought to be inherent within the certification/validation tests of a bio-pharmaceutical cleanroom.

Our product sales, engineering, and job management team begin by making a unified idea of your process and aims from the completion of our Custom made Estimate Ask for Form.

The Grade D ecosystem might be a background zone, depending on how your cleanroom is designed. This can be the the very least clean region with the GMP requirements for sterile merchandise.

A minimum amount 4" cove with the junction of floor and walls is usually recommended to aid cleaning. Modular wall devices Have got a recess that permits an fundamentally seamless junction amongst ground and wall. Each time a "stick-created" strategy is utilized treatment should be taken to design cleanable intersections of walls and floors.

Good practice along with any rules governing Organic and pharmaceutical processes performed inside the ability need to be adhere to as expected, and could modify a lot of the suggestions contained herein.

Grade B cleanrooms are essential for aseptic planning, filling, and compounding procedures. They Engage in a significant position in the subsequent pursuits:

Since the human overall body will come into immediate connection with beauty products and solutions, ISO 22716 standards mandate that almost all beauty items have to be bottled or crammed in just a cleanroom setting.

Ceiling complete need to be similar to that used about the partitions. The requirements for sanitizing ordinarily address the ceiling and also the partitions and ceiling substance and complete selection must reflect this. Suspended ceilings utilizing inverted "T" grid and lay-in click here panels may have a spot in that Section of the cleanroom suite not subjected to your rigors of normal sanitizing and where by the potential of trapped Areas to assistance organism development just isn't regarded a concern.

Such as Quality C cleanroom of a GMP facility, the Grade D region is utilized to accomplish fewer important measures in production sterile medications.

Tools must be made from components that happen to be appropriate While using the clean room environment and easy to clean. The equipment must also be on a regular basis preserved and validated to be certain it is actually performing the right way.

These qualification and validation stages call for very careful organizing, execution, and documentation. It can be crucial to work with knowledgeable industry experts to make sure the thriving qualification and validation of one's GMP cleanroom.

Cleanroom classification limits are normally standardized depending on industry standards and polices. Nonetheless, occasionally, limits can be adjusted determined by an intensive threat evaluation and scientific justification, thinking about the read more particular needs on the producing processes.

Alexa Vega Then & Now!

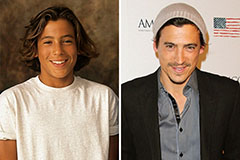

Alexa Vega Then & Now! Andrew Keegan Then & Now!

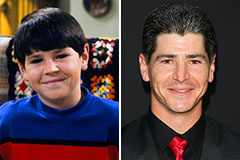

Andrew Keegan Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Kane Then & Now!

Kane Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now!